Thinking About Recognising Essential Elements For Rotor Pump

- Written by: admin

- Category: Uncategorized

- Published: April 2025

Refill the engine with fresh good quality oil. Don’t rely upon the dipstick until the car is back on all four wheels. Don’t over-fill getting this done. Not all engines take a whole 5 litres!

Priority #3: Normal maintenance like changing the engine oil, transmission fluid and engine coolant. This kind of maintenance doesn’t prevent catastrophic breakdown but is fundamental to keeping your older vehicle running its best for that longest possible time.

Install the wheel and hand tighten all lugs. Allow car to drop partially adding some weight to the wheels after which they tighten all lugs evenly with lug wrench.

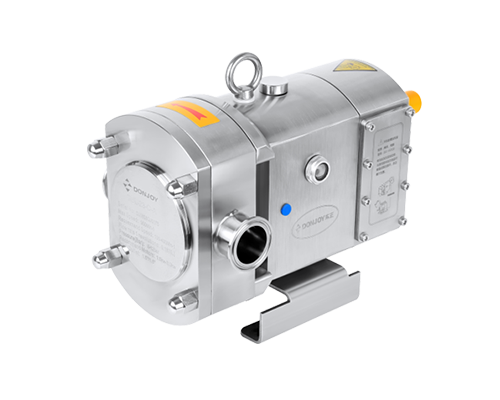

Remove Rotor Pump a single pad on the time this means you can re-install the 1 correctly and simply without making mistakes and having to begin. Follow along doing the doing the laundry the other pad. Each wheel has two pads that should be replaced.

To bleed your brakes and the complete system vertically fluid, first cover your bike with old newspaper or towels to avoid a grime. Remove 转子泵 out of your brake fluid container then locate the bleeder nipple on the caliper and take away the rubber cap next as well. Find some tubing that may fit into the nipple and place the opposite end into a waste gift basket. Use a wrench to begin the nipple about half a turn then squeeze your brakes as hard as you can and golf grip. Only release the brake lever after closing the bleeder breast.

Take the brake caliper off belonging to the rotor. Make use of a ratchet and socket to clear out the bolts securing the product. You then slide it at the top of the rotor. For that mean time, hang it to the frame employing a bungee cord.

After include done that, utilizing the lubrication provided by the kit, lubricate the interior of the impeller covering to improve installation faster. The lube will also aid to take out some with the chafing of your initial dry startup.

1941 saw the largest wind generator to dating. This generator’s capacity was 1.25 megawatts. It was known for the Smith-Putnam mechanism. The rotor measured an astonishing 175 feet in size.